The competitive landscape for commercial playground equipment has never been more fierce. Commercial playground equipment manufacturers seeking to leverage their brand while driving additional revenues need reliable partners that can deliver quality products at a competitive price.

For an equipment manufacturer or representative, playground safety surfacing is a natural choice for add-on sales. Although a significant share of the surfracing market is dominated by Engineered-Wood-Fiber (EWF), EWF presents little opportunity for add-on revenue due to its extremely low price point and relatively limited differentiation. On the other hand, recycled rubber products present a unique opportunity to fill the surfacing niche.

Recycled rubber products such as tiles, mulch and poured-in-place all have established a foot hold in the competitive surfacing market and each presents its own unique benefits as well as limitations. Understanding the limitations of each product and recognizing the differences between manufacturers is the first step in developing a supply program that can be used to increase revenues and operating margins per unit sales of equipment.

Synthetic rubber provides many wonderful benefits for playground surfacing. It is inorganic, extremely durable and provides unmatched resiliency. Recycled synthetic rubber (tire rubber) is also abundantly available and widely accepted as a source of playground safety surfacing.

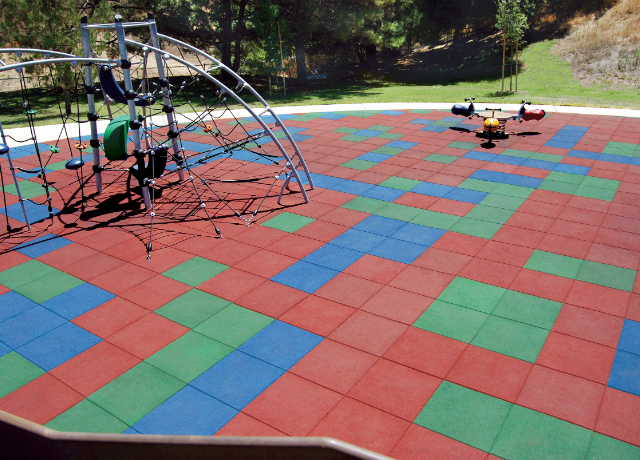

Recycled Rubber Tiles

Recycled Rubber TilesRecycled rubber tiles are made in a controlled environment at a manufacturing plant under optimum conditions. They are also produced using heat and pressure to achieve the highest level of density (greater durability) while also meeting critical fall height performance requirements.

The biggest challenge with rubber tiles is ensuring the tiles are properly conditioned at the time of installation to prevent installing tiles that have expanded in warmer weather (over sized) and that will subsequently shrink back to their natural state when the temperature cools

| Strengths | Weaknesses |

|

|

Recycled Rubber Pour-In-Place

Recycled Rubber Pour-In-PlaceRecycled rubber pour-in-place (PIP) is manufactured by the installer at the point of installation in a two layer system consisting of shredded recycled rubber buffings mixed with polyurethane binder and covered with a a wear course of virgin rubber mixed with polyurethane and hand-troweled into place.

The biggest challenge with PIP comes with the variability of the conditions during the manufacturing/installation, i.e. temperature, humidity, and installer awareness that all affect the performance of the finished surfacing.

| Strengths | Weaknesses |

|

|

Recycled Rubber Mulch

Recycled Rubber MulchRecycled rubber mulch is available in shred or nuggets that are colored at the factory using either pigmented polyurethane or latex coating. Rubber mulch is placed similarly to engineered wood fiber but typically requires less depth (6" versus 12") to achieve the required critical fall height rating.

The biggest challenge with rubber mulch is maintaining the proper depth with active playground use. Rubber mulch surfacing needs routine maintenance to ensure proper depth and often needs replenishment over time to replace rubber carried away through normal playground use.

| Strengths | Weaknesses |

|

|

You have worked hard to build your brand reputation. You have carefully selected the products you offer taking not only the product quality and fitness of application into consideration but also the reputation of the supplier and their track record of firmly standing behind their products.

Choosing a surfacing partner should entail the same level of due diligence on your part as you put into selecting any other products or materials you sell. With so many choices and options available in the market, how do you make your choice?

Quality - First and foremost your surfacing partner should have a clear track record of producing products that perform and last as intended. Although surfacing performance is highly dependent on proper installation, a good surfacing system starts with a quality product.

Service - You build trust with your customers and stake your reputation on the products and services you provide. Your surfacing partner must be able to balance the intricate dynamics of real world applications regardless of"fault" while supporting your efforts to find real solutions to the inevitable problems that will arise.

Selection - One size never fits all. In addition to the practical performance needs, buyers often demand specific aesthetic requirements when choosing their surfacing option. Off the shelf manufacturers often limit the color choices available or are constrained by their own marketing agendas when establishing product availability. Determine what your needs are and how you market your products and incorporate that criteria into your evaluation. If you offer your customers a high degree of customization, customization should be available through your surfacing partner.

Value - Whether you are negotiating multi-year contracts or bidding individual projects, delivering value differentiates you from your competition. Your surfacing partner should be part of your overall value proposition. This is a summary of the benefits you will deliver minus the costs and risks associated with receiving those benefits. What you offer is not evaluated in a vacuum. It is constantly compared to the value proposition of your competition. By selecting quality partners that stand behind their products you minimize risk and increase your value. Reduce wasteful cost such as freight by partnering with suppliers that can cost effectively meet your diverse geographic needs. Understand all of the variables that collectively determine the value proposition to create the best opportunity to select the right partner.

Building additional revenue and profits through existing sales channels can be as easy as tapping into adjacent sales on existing opportunities. For a playground business adding surfacing to equipment and amenities sales is a natural fit. By understanding the various options available, a playground company can effectively source, evaluate and secure a reliable channel partner that will compliment their business model and give them a piece of the surfacing market sales and profits.